Our Story

M/S Maa Bairakali Plywood Industries revolves around achieving excellence in the fabrication of plywood products. Strong commitment towards quality, innovation, and sustainability has turned us into a name of repute within the plywood market segments.

It started with a passion-to be able to assist customers in their ever-growing needs with plywoods that are reliable and long-lasting. This has transformed into pride today, as we are offering a wide range of products-from marine-grade plywood to borer-proof panels and many more, designed to meet broad-based demand emanating from construction, interior design, and industrial sectors.

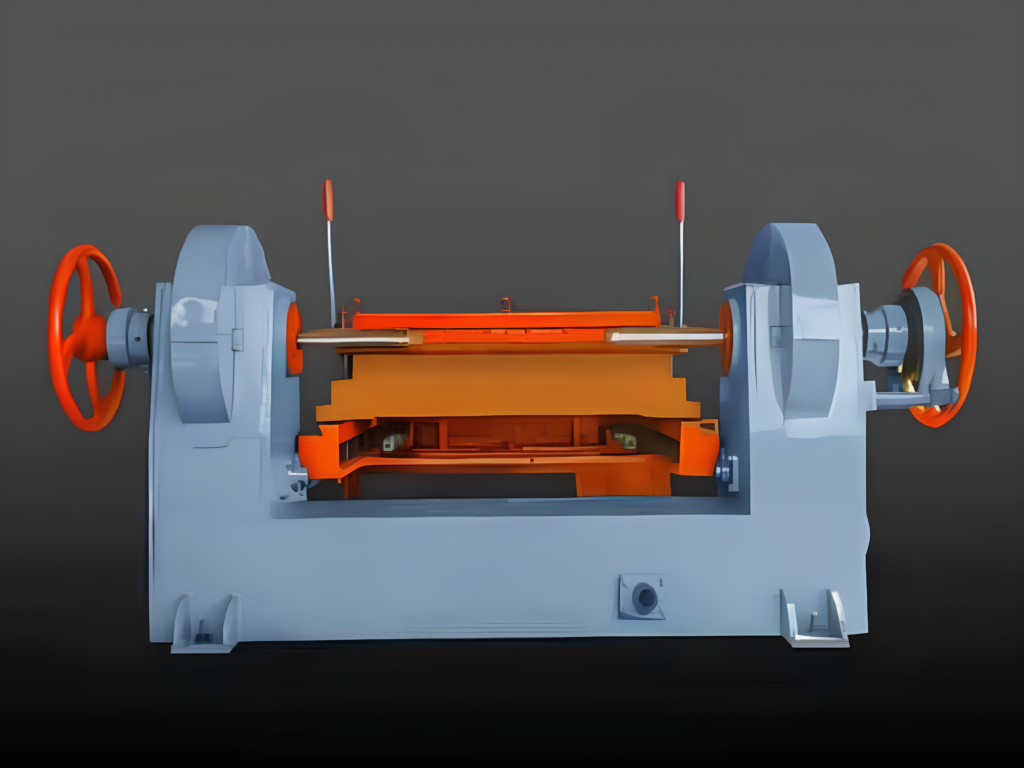

Unwavering concentration on quality at every stage of product processing characterises us. Thus, state-of-the-art technology and the finest raw material ensure that every sheet of plywood meets the most rigorous quality criteria and provides strength, durability, and longevity. Whether it is a commercial project or renovation at your house, our products are committed to superior performance in all conditions.

At M/S Maa Bairakali Plywood Industries, sustainability is intrinsic to all our business operations. We follow an eco-friendly way of doing business, sourcing our timber in an environmentally friendly manner with negligible impact on the environment.

By taking a more customer-oriented approach, we cultivate extraordinary service and lifelong relationships with our clients. Innovation and quality further propel us to continued growth as an industry leader, providing for you solid products that marry beauty, strength, and sustainability.

Join us in building the future with plywood solutions you can

Trust.

What Drives Us

Our vision is to become a leading provider of reliable and long-lasting plywood solutions, driven by innovation and a commitment to quality. We aim to set industry standards in sustainability, offering eco-friendly products that meet the highest expectations of strength, durability, and performance.

At M/S Maa Bairakali Plywood Industries, our mission is to deliver superior plywood products that combine beauty, strength, and sustainability. We are committed to maintaining high standards of quality at every stage of production, fostering lifelong relationships with our clients through exceptional service, and conducting business in an environmentally responsible manner. We strive to build the future with plywood solutions that customers can trust.

Future Aspirations

Our Process

1. Selection And Sectioning Of Logs

2. Peeling Of Logs

Timeline of Process